-

Your shopping cart is empty!

Menu

Your shopping cart is empty!

Electric gates are powered by electricity. So, what happens to them when there’s a power cut, or the workmen dig up the road and cut off the electricity? And how do the gates open and close when they need electricity to work? This piece will demonstrate how to open electric gates when there is no power.

The most common gates are swing gates and sliding gates.

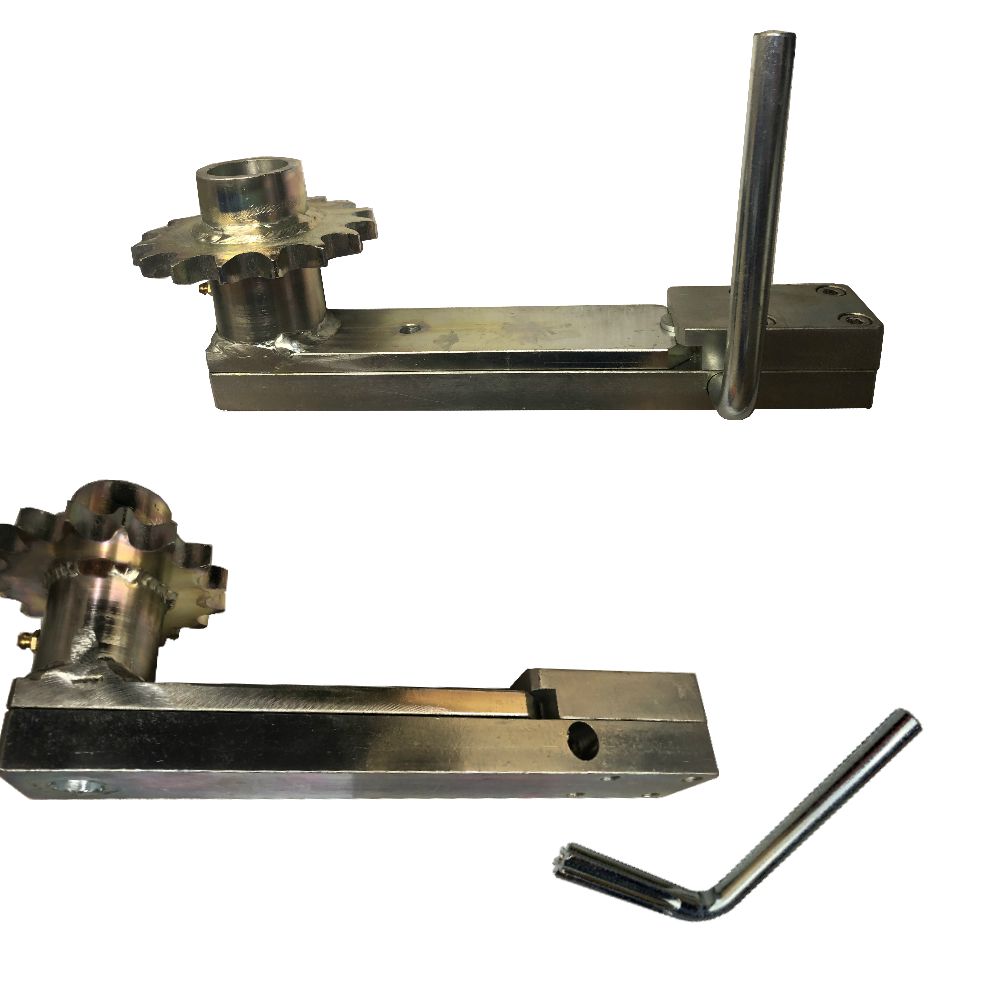

Sliding gates are the simplest, as the gate has wheels which run along a track across the driveway entrance. A toothed rack is mounted along the length of the inside of the gate. A gear on the outside of the sliding gate motor meshes with the rack on the gate. Consequently, when the gate motor turns, the gate is opened or closed.

Learn some of the benefits of sliding gates here.

Swing gate motors are a little more varied, but all use one of two basic operation principles. An electric gate motor either turns an arm mounted to the gate to open or close it, or it moves the point where it connects to the gate toward or away from the point where it is connected to the gate post; this opens and closes the gate.

Learn some of the benefits of swing gates here.

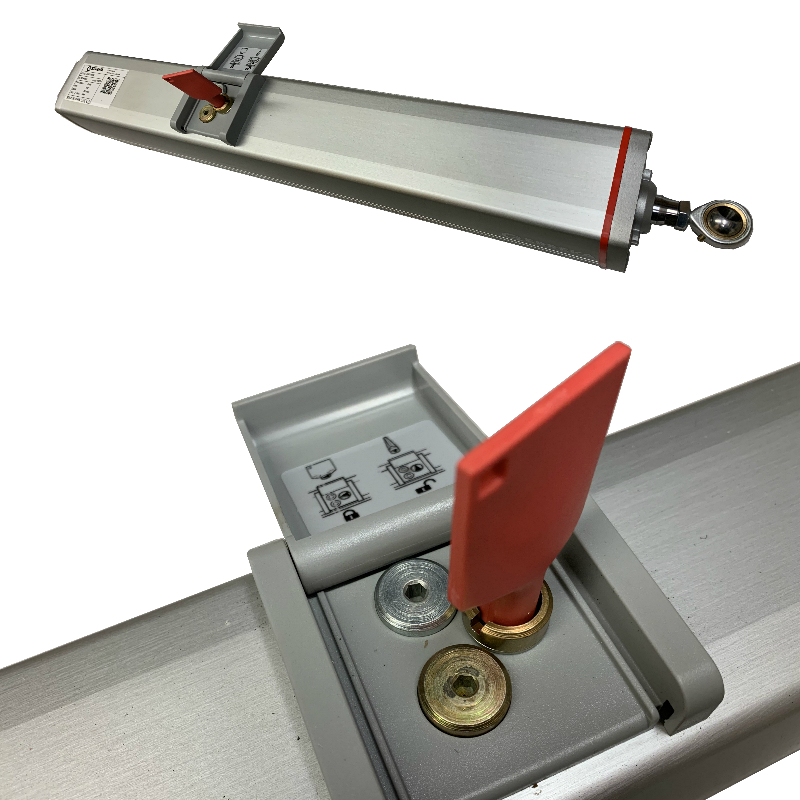

The method used to operate electric gates manually, when there is no electricity to power the motors, is called manual release. This involves the use of a manual release key and built-in manual release mechanism, or a separate additional manual release mechanism.

The manual release key is usually inserted into the appropriate lock on the motor housing, then a lever or handle is operated to disconnect the motor drive from the gate opening arms, gears and shafts.

With most systems, operating the manual release doesn’t necessarily allow the gate to move completely freely.

There are often parts of the gate drive mechanism that will still move when the gate is moved by hand. Hydraulic operators will also have oil in the system that must be pushed back through valves.

So, while a manual release system allows a gate to be moved without the motors, there is likely to be some resistance and the gate should be pushed slowly and steadily.

Some manual release mechanisms will not operate when they are under pressure. In these situations, the gate must be pushed against the desired direction to relieve the pressure and allow the release mechanism to operate. The simple rule is never to force a manual release system.

Spare manual release keys and mechanisms can be bought from Linkcare, but many manual release systems are operated with a numbered key. Keeping a record of the key number is recommended, as it makes ordering more much easier!

It’s also a good idea to leave a note of any manual release key number in the gate’s control cabinet to help a gate engineer carrying out servicing or repairs.

As the manual release is normally only for emergency purposes, it is rarely used. This means that they can become dirty and stiff, and sometimes impossible to use just when they’re really needed.

We strongly advise that manual release mechanisms should be tested every three months or so, and suitable maintenance carried out at least once a year. This is likely to involve cleaning, lubricating and testing.

All automated gates installed by a qualified gate engineer should have a manual release system and anyone who uses the gates should be aware where the manual release keys are kept.

By disconnecting the gate from the operator, manual releases also ensure that anyone trapped by badly designed or unsafe gates can be released.

Here at Linkcare, we are the UK’s largest independent supplier of kits and parts for gate automation. For more information, call us on 01895 232626 or visit our contact page.

These cookies are required for the website to run and cannot be switched off. Such cookie are only set in response to actions made by you such as language, currency, login session, privacy preferences. You can set your browser to block these cookies but our site may not work then.

These cookies are usually set by our marketing and advertising partners. They may be used by them to build a profile of your interest and later show you relevant ads. If you do not allow these cookies you will not experience targeted ads for your interests.

These cookies allow us to measure visitors traffic and see traffic sources by collecting information in data sets. They also help us understand which products and actions are more popular than others.

11 Comment(s)

That is great I have overridden but how do i reconnect

I have lost the key to my electric gates, is it possible to purchase a replacement. I don't have a number for the key. Thanking you Teresa Ryan

Hi I am trying to find a gate manual release key which has seven spokes/gears with a max CIA of 1.25cm. Do you have anything like this please? Thank you Miles

Hi I am trying to find a gate manual release key which has seven spokes/gears with a max CIA of 1.25cm. Do you have anything like this please? Thank you Miles

Hi Do you have a brand name for your system? You can send pictures to info@linkcare.net or call us discuss on 01895232626 If you check on the motor there should be a brand name.

can you help me ive got roller genius gates and the 3 amp fused spur outside keeps blowing. So for now I need to open them manually I've turned the key as per manual but there is still aoot of resistance is this normal??? Help as I need my van out for work

can you help me ive got roller genius gates and the 3 amp fused spur outside keeps blowing. So for now I need to open them manually I've turned the key as per manual but there is still aoot of resistance is this normal??? Help as I need my van out for work

What happen if i lost my key? is it possible to purchase a new key?

Hi, It is normally possible to get replacement keys once the correct key has been identified. Please either call us on 01895 232626 to discuss, or send you contact information together with pictures of the equipment you have installed to sales@linkcare.net

This article is very informative and I feel like you are reading my mind

Electricity went tried to open it manually with the key but it was so stiff that the key broke.Can I get a replacement key the key# is 605 I am in Jamaica West Indies

how much money for a set of driveway gate 1 2ft wide 5.5 ins high I would like a quote thanks

Hi Michael, our gate prices depend on the design and finish you require. If you could email me on salessupport@linkcare.net I can give you more information,

Leave a Comment