-

Your shopping cart is empty!

Menu

Your shopping cart is empty!

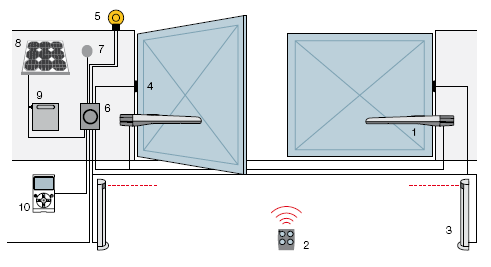

A gate automation system is an often-complex ‘machine’ designed to open and close gates regularly and safely at any time. With many moving parts and exposure to the elements, a gate automation system needs regular maintenance to keep it working as it should.

The individual components that make up a gate automation system are varied and often complex. Electric motors or hydraulic drives operate gears connected to arms or brackets fixed to your gates. Modern electronics are used in control panels, photocells, loop cards, safety edges and transmitters and receivers.

It doesn’t matter what combination of sliding or swing gates, control panels, motor voltages, safety devices and access control is used. Maintenance is vital to ensure that your gates work smoothly and safely and to reduce the possibility of expensive and time-consuming automatic gate system breakdowns.

The frequency of maintenance for any gate system may be affected by the frequency of use of the gates. Electric gates that are opened and closed all day long are more prone to wear-related issues than gates that open once or twice a day. But gates that aren’t used for a few days at a time may need more servicing that focusses on keeping components moving freely.

Location of a gate automation system may play a part in determining how much servicing is required. If the gates are near the coast, strong winds and salt spray from the sea can reduce service intervals. But the essence of good gate breakdown preventative maintenance is a service from an experienced gate installer at least once every year.

Ideally, the gate engineer who installed a new gate automation system will advise on the level of servicing. If you have moved into a house with automated gates and are unsure about their service history, calling a qualified local gate engineer is a wise move. They will be able to assess the overall condition of the gate automation system and carry out any required servicing and maintenance work.

Essentially, gate automation system maintenance should include the following:

Inspecting the physical integrity of the gates

Checking the correct operation of hinges and stops, and lubricating where required

Checking the automation system for correct operation

Cleaning and lubricating areas where metal moves over metal

Checking and testing all cable connections to ensure nothing is coming loose

Checking and testing electronic equipment for the presence of smaller pests such as slugs spider and insects which can damage circuit boards and affect photocell operation

Checking all enclosures and cable entries or any signs of water ingress

Testing all safety devices, obstacle detection systems and warning devices for correct and safe operation

Cleaning underground boxes

Lubricating linkages

Ensuring underground boxes have sufficient drainage to prevent motors from sitting in water for more than half an hour.

Manual release devices should be tested, cleaned and lubricated as required

Sliding gate wheels and rollers should be checked, cleaned adjusted and lubricated if required

End stops and racking should be checked to ensure secure fitting

All access devices should be checked – radio controls, keypads, intercoms etc.

The oil levels of any hydraulic operators should be checked and topped up if required. The area around the operators should be checked for any signs of leakage, which could indicate that the unit requires a service by the manufacturer.

There are a few things owners of gate automation systems can do themselves to help reduce maintenance requirements as follows:

Manual release devices should be operated three or four times every year to keep the mechanism from seizing due to lack of use

The area around automated gates should be kept clean and free from debris and loose stones

In areas prone to slug damage slug traps, pellets or slug wool can be used to keep slugs away from vulnerable electronic circuit boards

Gravel laid below the control box will also help to deter slugs.

If you have any questions about gate automation system maintenance or are looking for a trusted and qualified gate automation engineer in your area, contact Linkcare on 01895 232 626.

These cookies are required for the website to run and cannot be switched off. Such cookie are only set in response to actions made by you such as language, currency, login session, privacy preferences. You can set your browser to block these cookies but our site may not work then.

These cookies are usually set by our marketing and advertising partners. They may be used by them to build a profile of your interest and later show you relevant ads. If you do not allow these cookies you will not experience targeted ads for your interests.

These cookies allow us to measure visitors traffic and see traffic sources by collecting information in data sets. They also help us understand which products and actions are more popular than others.

1 Comment(s)

Great insights! Regular gate servicing is crucial for longevity and optimal performance. Your advice on the frequency of maintenance is helpful for homeowners and businesses alike. It's true that preventive care reduces the risk of unexpected issues and ensures the security of the property. I appreciate the emphasis on professional servicing and the importance of using genuine replacement parts. Keep up the informative content!

Leave a Comment